Vertical Roller Mill Wear Segments المزود

Influence of quartz particles on wear in vertical roller mills.

2010年4月1日 A laboratory scale vertical roller mill with a transparent roller/table has been developed to further understand the material movements during grinding. The

[خذ المزيد]

Influence of quartz particles on wear in vertical roller mills.

2010年4月1日 The standard closed circuit comminution process commonly employed in industrial vertical roller mills has been analyzed to determine the influence of typical

[خذ المزيد]

Wear mechanism of abrasion resistant wear parts in raw

2011年9月2日 A laboratory scale vertical roller mill with a transparent roller/table has been developed to further understand the material movements during grinding. The

[خذ المزيد]

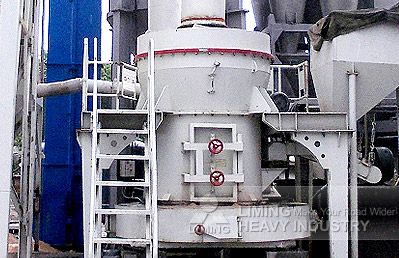

VERTICAL ROLLER MILLS A holistic VRM approach

2022年4月4日 The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and

[خذ المزيد]

Wear mechanism of the rollers of MPS vertical roller mill

Abstract: This article, based on the abrasion condition of the rollers on the working field, analyzes the movement characteristics of the material layer of the vertical roller mills

[خذ المزيد]

Coal mill, gypsum mill, clay mill, etc. Pfeiffer MPS mills

MPS vertical roller mill. The versatile MPS vertical mill – with a fine tradition of quality grinding. Highest flexibility with constant product quality, individually conceived, suitable

[خذ المزيد]

OK™ Pro+ ceramic wear segments for vertical roller mills

2020年11月4日 segments for vertical roller mills. WE DISCOVER POTENTIAL. Long-lasting, high-quality and recyclable ceramic wear segments . Designed specifically for

[خذ المزيد]

Roller Mill - Springer

2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers)

[خذ المزيد]

Vertical roller mill for raw Application p rocess materials

2016年1月4日 The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills. These days, the vertical roller mills have been widely

[خذ المزيد]

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from... Find,

[خذ المزيد]

ATOX® Coal Mill - FLSmidth

A compact coal mill solution for grinding virtually any type of raw coal. Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal. The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate ...

[خذ المزيد]

Roll Mill Grinding Rolls And Bull Ring Segments

2367 LAKESIDE DRIVE, SUITE A-1 BIRMINGHAM, AL 35244 PHONE . roll. If bull segments are the new of the rolls and the ring segments wear at an accelerated rate as cause mill run-back or trip due to high mill motor .

[خذ المزيد]

Ceramic wear segments - Vertical Roller Mill.

2022年1月20日 Roller tyres and table segments are manufactured with high chromium base layer with ceramic inserts. The manufacturing of Metal Ceramic Composites is a special process that involves ceramic precast body chemical plating, mixing, sintering, suction, casting and an optimised heat treatment process to ensure that the cast

[خذ المزيد]

Cement Industry » Engineered hardfacing solutions to fight wear

Following are a few examples where Hardcarb anti-wear solutions are regularly offered: Roller Presses – cheek plates, roller refurbishment and profiling. Kiln and Coolers – bucket elevators, immersion tubes, clinker chutes, cooler grate plates, ID fans. Transport and Storage – pipes, elbows, bends, dust collectors, ESP ducts, fans, silos ...

[خذ المزيد]

VERTICAL ROLLER MILLS A holistic VRM approach

2022年4月4日 VERTICAL ROLLER MILLS 1 SEPTEMBER 2021 INTERNATIONAL CEMENT REVIEW P ut simply and briefly, thyssenkrupp’s quadropol® vertical roller mill (VRM) remains one of the leading VRMs in the market in terms of its simple and compatible design structure. Requirements by plant operators for a reliable solution, as well as not

[خذ المزيد]

Premium solutions for the cement industry - FLSmidth

SAG Mill; Roller presses Roller presses. High pressure grinding roll (HPGR) ... KREBS® vMAX™ Vertical Slurry Pump; ODS Diaphragm Pumps; Slurry Valves Slurry Valves. ... Mill liner wear measurement and prediction services. Back. Mill Liners. Back. Rod Mill. Back. Rotary Scrubbers. Back. SAG Mill.

[خذ المزيد]

OK™ Raw and Cement Mill - FLSmidth

Smart vertical roller mill design for raw, cement and slag grinding. The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between ...

[خذ المزيد]

Cement mills and raw mills for small to medium throughput

MVR vertical mill with conventional drive: economical solution for small to medium output rates. For the preparation of cement raw material, cement, and granulated blast-furnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice. This mill type is by the way the core piece of our modular ready2grind ...

[خذ المزيد]

Wear Mechanism of Abrasion Resistant Wear Parts in Raw

2020年7月15日 The table is driven by an electrical motor and the rollers These high chromium alloys are used in closed circuit dry grinding rotate due to the frictional force established in the grinding bed. vertical roller mills (VRM) as wear liner on both table and rollers The grinding force is made up of the net weight of the rollers and (Fig. 1). The ...

[خذ المزيد]

OK™ Pro+ ceramic wear segments for vertical roller mills

2020年11月4日 wear liners in vertical roller mills (VRMs) is to reweld or hard face the worn surface. This means regularly stopping the mill. Because the ... OK Pro+ plus ceramic wear segments for vertical roller mills 9 /24/2020: FLSmidth A/S: Vigerslev Allé 77: DK-2500 Valby Copenhagen: Tel: +45 3618 1000

[خذ المزيد]

Grinding Roller Tires - Imcoalloys

Most cost effective solution. Most advanced Metal Matrix Carbide Composites. Maximum Wear Abrasion Resistance. Can be easily retrofitted to any conventional Grinding Roll. Reduced weight of grinding roller tire up to 10%. Easy replacement process. Hence reduces maintenance cost. High efficiency in grooving. Saves downtime and production cost.

[خذ المزيد]

(PDF) WEAR ANALYSIS OF VERTICAL COAL MILL PLATE

2022年11月1日 vertical roller coal mill Int. J. Coal Prep. Util. 00 1 – 15 [2] Thyssenkrupp Industrial Solution 2016 Hous ing unit QMK 32/16/Dia.4 [3] Welding alloys group 2016 Hard lite TM

[خذ المزيد]

Hardfacing Rebuilding - Ecorporates

We can rebuild wear segments of Rollers tables which are worn up to 100mm. We have completed rebuilding tasks for different Vertical Mills. Today Ecorporates rebuilding service is the most reliable and cost saving

[خذ المزيد]

OK PRO+ Ceramic Segments for OK™ Vertical Roller Mills

Improve mill productivity with fewer maintenance stops While we may be experts in mill technology, we can’t actually stop wear in your OK™ mill. But what we can do is make sure that the interval between wear lining maintenance stops is as long as possible – up to 2.5 times longer than alternative wear solutions. This means your mill is up and running for

[خذ المزيد]

Cement mills and raw mills for high throughput rates - Gebr.

Depending on the abrasiveness of the material to be ground and areas to be protected, different wear materials are used on our vertical roller mills. Alloy cast iron as per DIN 1695, hardfaced cast iron or composite materials with high-chromium inserts in ductile base materials: the grinding elements designed by Pfeiffer are made of high ...

[خذ المزيد]

quadropol® thyssenkrupp Polysius Grinding Technologies

The quadropol® concept for coal or pet coke grinding, with adapted table speed and high efficiency separator sepol®, ensures a safety mill operation and serves reliable the kiln burning process. Mombasa Cement Ltd. ordered a QMK² 24/12 with three roller units for the 5,000 tons per day kiln line.

[خذ المزيد]

Influence of quartz particles on wear in vertical roller mills.

2010年4月1日 Influence of quartz particles on wear in vertical roller mills. Part I: Quartz concentration @article{Jensen2010InfluenceOQ, title={Influence of quartz particles on wear in vertical roller mills. Part I: Quartz concentration}, author={Lucas R.D. Jensen and Henrik Friis and Erling Fundal and Per M{\o}ller and Per Bruun Brockhoff and Mads ...

[خذ المزيد]

Wear mechanism of the rollers of MPS vertical roller mill

This article, based on the abrasion condition of the rollers on the working field, analyzes the movement characteristics of the material layer of the vertical roller mills from several aspects, such as the tangent speed difference between the roller and the grinding table, the "piles up" phenomenon as well as the flow forms of the material layer. Then we further

[خذ المزيد]

MAAG® GEAR MAX Drive System - FLSmidth

True strength from our modular drive system for vertical roller mills. Our three-stage spur gear unit with torque split, the MAAG® GEAR MAX Drive system uses two equal drive units to deliver power up to 15,000 kW for your vertical roller mill. We’ve taken the expertise in gear technologies and manufacturing we’ve built up over the last 100 ...

[خذ المزيد]

Maintenance of wear parts for a ball mill and vertical mill

2017年8月3日 The wear rate measured in gram per ton of cement produced is much higher for a ball mill than for a vertical roller mill. However, the unit cost for wear parts for a ball mill is much lower than for a vertical roller mill. For a ball mill grinding OPC to a fineness of 3200 to 3600 cm 2 /g (Blaine) the cost of wear parts (ball, liners and mill ...

[خذ المزيد]- طحن وسحق مطحنة

- تستخدم مطحنة الكلمة ملموسة للبيع كسارة آلة للبيع

- الكوارتز لتجهيز الطاحونة

- تستخدم مصانع الفرز المتنقلة

- السعودية ريمون مطحنة السعر

- كيفية_عمل_غسالة_الرمل_البحري

- مصانع الرأسي لإنتاج الكالسيت

- الكسارات الصينية مبيعات

- چگونه به استفاده از ماشین خشک

- مطحنة الكاولين ميكرون

- مطحنة ريموند لإنتاج التعويم

- تولیدکننده آسیاب طلا در چین

- الأردن كسارة الفك التمهيدي

- حجر المطحنة آلة جرار أستراليا

- شنغهاي shindang محطم المعدنية

- معدات البناء كسارة الحجر البناء في البنجاب

- تأثير الفيديو محطم

- ورقة الحجر آلات الموردين في كسارة متنقلة الهند

- إنتاج مسحوق طاحونة الخبث العمودي

- comment obtenir les boosters gratuits dans candy crush

- استخراج الجبس من المحاجر

- مزايا الفحم التفاعلية للأطفال

- الرأسي مطحنة الأسطوانة صناعة الاسمنت

- دستگاه های سنگ شکن شن و ماسه در متر ernakulam از

- مصنع فرز الحصى

- نقاط الانبعاث في كسارة الصخور

- عملية خط إنتاج الحجر

- مسحوق كسارة آلة

- كم مستويات الرمل محطم الحجر

- خطة خطة عمل لتصنيع الطاقة الشمسية

© Copyright - PETER&X محطم